Trotec

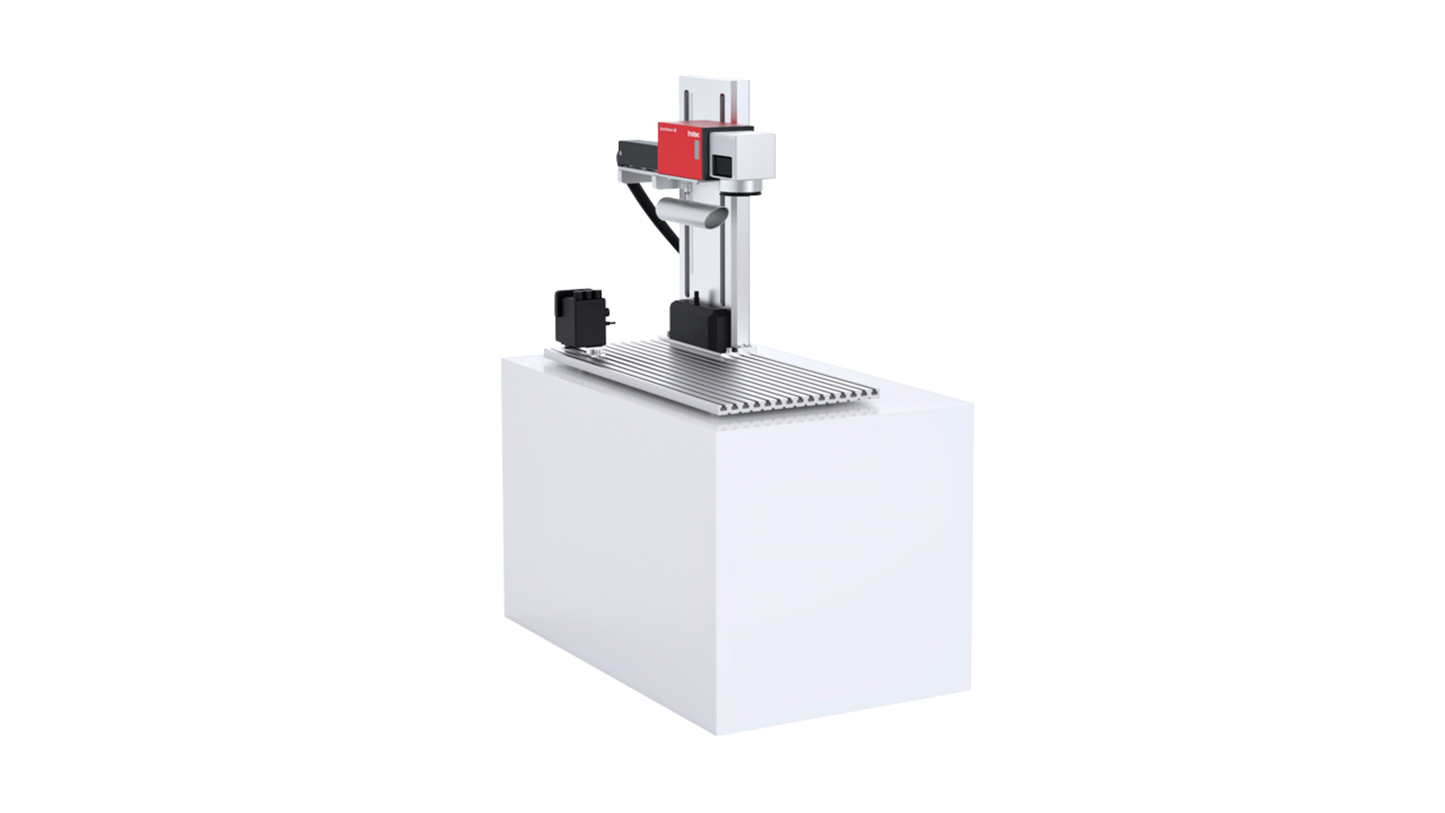

Trotec SpeedMarker 100

Trotec SpeedMarker 100

Regular price

﷼394,000.00 SAR

Regular price

Sale price

﷼394,000.00 SAR

Unit price

per

Shipping calculated at checkout.

Couldn't load pickup availability

Laser Marking Machines - SpeedMarker Series

The use of SpeedMarker marking lasers supports automation processes. Due to the simple laser marking of dynamic data and infinite possibilities in AdvancedScripting®, the SpeedMarker series is exactly the right choice for machine manufacturing, electronic industry and job shoppers. Individual components as well as large batch sizes are marked with a Galvo laser class 2 system for complete traceability, brand communication or with functional markings.

SpeedMarker laser marking machines - Created for automation

Benefits of the SpeedMarker Galvo Laser Marking Machines

Automation-friendly interfaces

Automated productivity The SpeedMark® laser software not only centrally controls the laser process, but also offers automation-friendly interfaces for connecting external data and control commands. Infinite scripting possibilities guarantee consistent quality for recurring markings. The legibility of the laser marking is guaranteed by high-quality optics and components. Irrespective of whether many small components or large individual parts are involved.

Thanks to the large processing area of the SpeedMarker 1300 to 1600, a large number of small components can be marked with individual data as well as large-volume individual parts in a single operation. Special parts can also be adequately marked despite time pressure in line production.

Reduce commissioning and cycle times

Instant productivity The SpeedMark® software convinces with its graphic process-oriented user interface. This means that laser marking processes can be visually mapped without extensive previous programming knowledge. The Focus Finder helps to reduce commissioning times. You can do easy, fast and high quality marking on 3D objects like tilted planes, balls and bowls, cylinders and inside tubes. With this you get the most productive virtual rotary. The integrated parameter database for various materials also helps to save time and money. This reduces your rejects to a minimum, both for custom-made products and in series production.

Maximum laser and machine safety

Reliable productivity Software and laser machine are designed to ensure not only simple and intuitive handling, but also full safety in handling the laser cell. All functions and productivity-enhancing options always take maximum laser and machine safety into account. This includes automated lift doors and rotary indexing tables for rapid part changes and the machine lighting and window concept for operator and work ergonomics.

Downloads